Number of hours

- Lectures 22.5

- Tutorials 24.0

- Laboratory works 4.5

- Written tests 3.0

ECTS

ECTS 4.0

Goal(s)

- Understand a company's planning system

- Understand the principles of product quality, production and service

- Understand the impacts of variability on quality

- Understand environmental impacts of a product by analysing its life cycle

Content(s)

The aim of this course is to present tools which allow companies to be efficient in areas such as quality, cost, deadlines and environment.

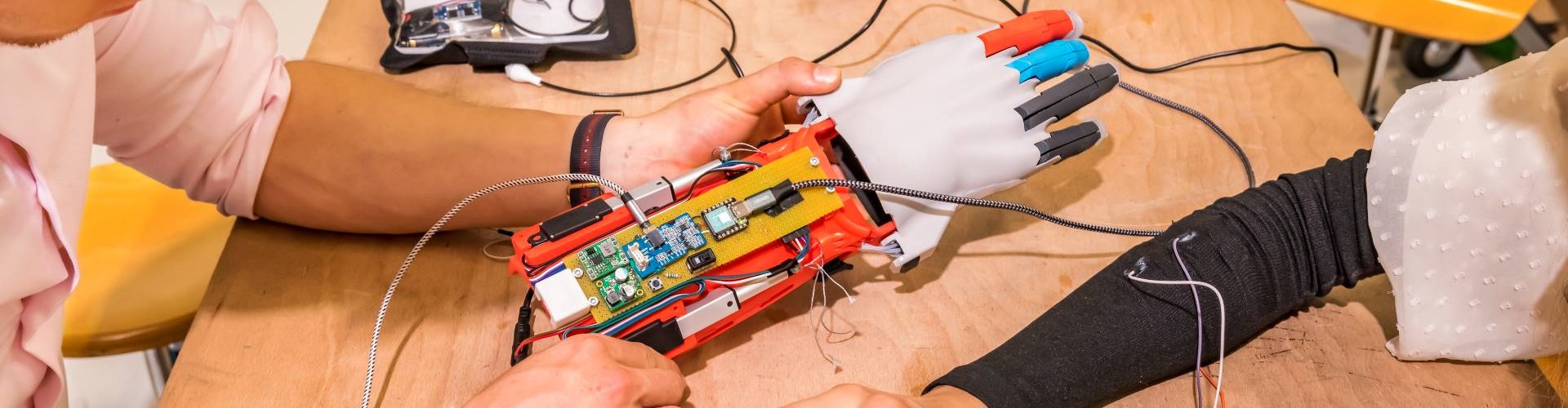

- Production Management (Lectures = 10.5 hours, Tutorials = 9 hours, Practical work = 4.5 hours)

In this section traditional tools will be presented and then applied in the tutorials and practical work.- Planning levels

- Management of production resources: MPR I et II

- Just in Time (JIT) principles (Kanban, SMED, 5S...)

- Stock management: Economic Order Quantity (EOQ)

- Management of product quality, production and service (Lectures = 9 hours, Tutorials = 7.5 hours)

This section consists of a presentation of the concepts needed and applied for a quality system in production.- Continual improvement principles

- Measurement System Analysis

- Statistical Process Control

- Environmental Management (Lectures = 3 hours, Tutorials = 7.5 hours)

In this section, theoretical points will be studied concerning the definition of environmental impacts caused by products, services, systems etc. Different types of impacts will be studied and also the reasons for calculating them (market, customers, design, legislation, eco-labels etc...) using a Life Cycle Analysis (LCA) approach. The tutorials will allow students, through a concrete example of "rechargeable batteries or not", to use a LCA software used in companies to calculate environmental impacts. This exercise will show and highlight the limits of using the LCA method and the difficulties encountered.

Prerequisites

No prerequisites needed

Continuous assessment (CC) = Study reports on tutorial classes

E1 = Final written exam from 1st exam period - duration 3 hours

E2 = Written exam from 2nd exam period - duration 3 hours

N1 = Final mark from 1st exam period

N2 = Final mark from 2nd exam period

N1 = 0,3*CC + 0,7*E1

N2 = E2

A. Courtois, M. Pillet, C. Martin-bonefous. "Gestion de production", Editions d'Organisation, 2006

V. Giard. "Gestion de la production et des flux", Economica, 2003.

D. Trentesaux and O. Sénéchal, "Conduite des systèmes de production manufacturière", Techniques de l'ingénieur, 2002

ISO 9000. "Systèmes de management de la qualité - Principes essentiels et vocabulaire", 2000.

Afnor. "Méthodes statistiques, Tome 4 : Maîtrise statistique des processus." AFNOR, 7 edition, 1996.

French State controlled diploma conferring a Master's degree