Collaborative Manufacturing Tasks for All Workers

Every person has the right to reach personal satisfaction through work

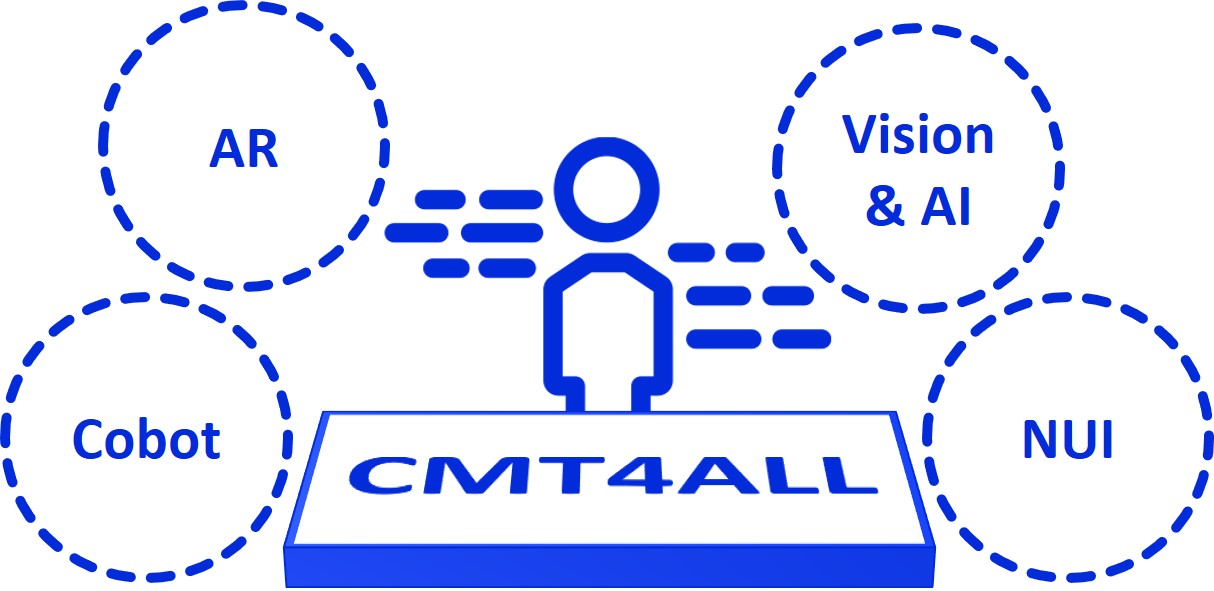

CMT4ALL is developing a collaborative manufacturing cell solution for workers with disabilities, to access manufacturing jobs they would otherwise not be eligible for. The manufacturing cell will use automation technologies such as Safe Collaborative Robot, Augmented Reality, Natural Interaction, Visual Inspection and Artificial Intelligence.

New Employment Opportunities

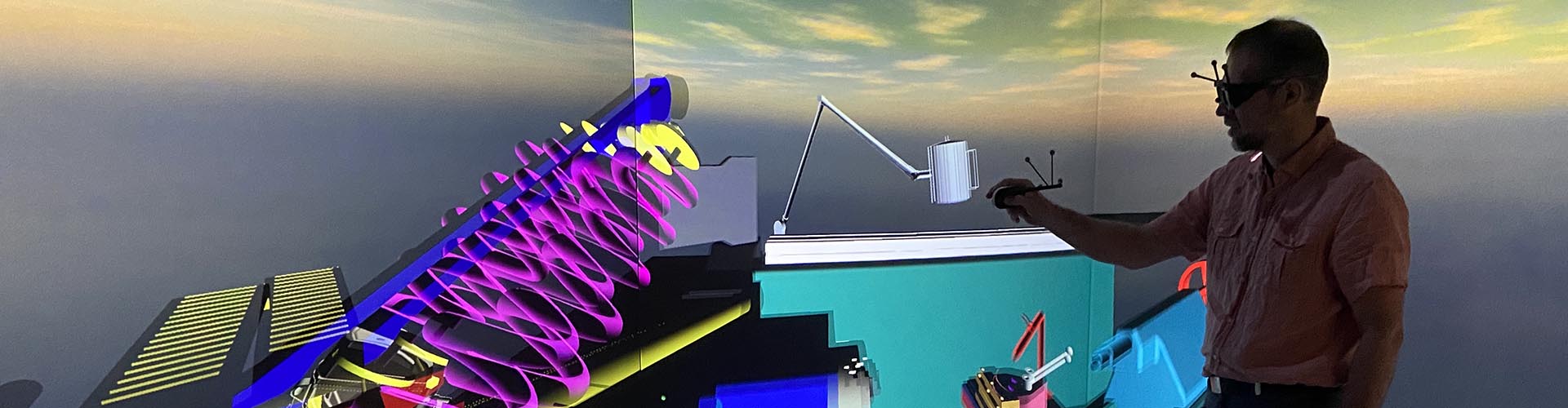

Automation technologies are creating new and exciting employment opportunities in industry for workers with disabilities. As a result, and focusing on industrial collaborative tasks, workers that previously could not apply for certain jobs are able to access them after partnering with interactive collaborative technologies.

In CMT4ALL project, design-for-all principles are applied to develop a collaborative manufacturing cell that complements the worker’s skills, capacities, and capabilities required to access the job in different manufacturing scenarios.

A Co-Working Human-Machine for Socially Sustainable Manufacturing

This collaborative workstation, will meet the flexibility demands in industry: flexibility in production and flexibility in workercapabilities. It will be designed and implemented with a broad range of worker profiles in mind. The cell will provide a flexible solution based on a set of features and functionalities, as manufacturing process, quality insurance and worker guiding capabilities.

The worker will also be able to steer some aspects of the cell configuration through interaction with it, thus preserving a sense of control over the collaborative process.

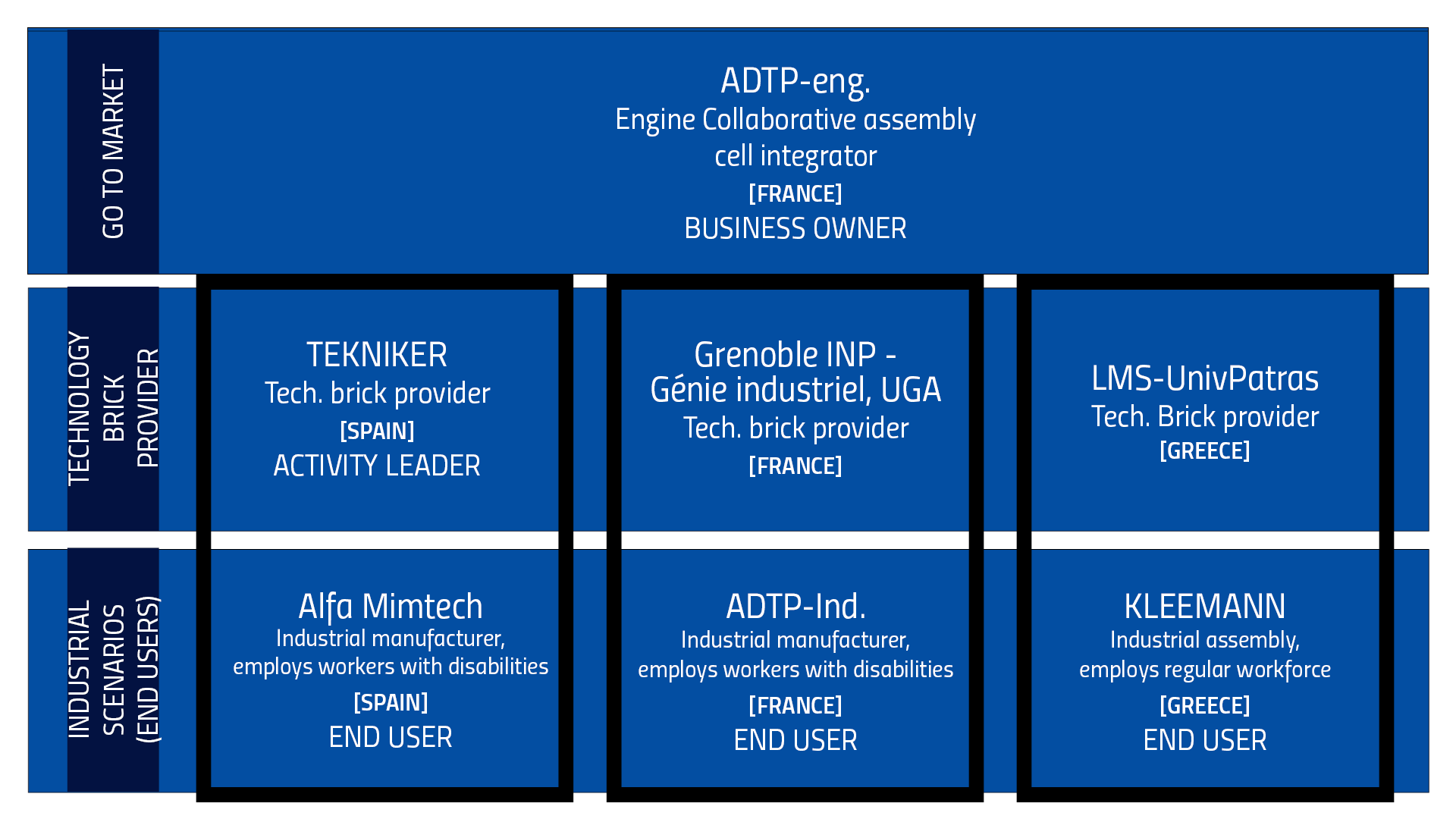

Partners and funder

Linkedin : https://fr.linkedin.com/showcase/cmt4all