Number of hours

- Lectures 24.0

- Projects -

- Tutorials -

- Internship -

- Laboratory works 24.0

- Written tests 2.0

ECTS

ECTS 3.0

Goal(s)

This course teaches a variety of organisational and technical tools that could/should be involved in Product Development Projects. The following themes will be addressed, some are mandatory some are optional.

Mandatory themes:

- Project Management

- System Engineering: Operational Safety

First option, choose one among:

- Innovation

- Design for Manufacturing

Second option, choose one among:

- Design of Experiments

- Prototyping Techniques

Only a few hours of lecture or tutorials will be dedicated to each theme, but the next goal is to apply the theme in your project. This is to ensure the acquisition of know-how through practice, under a "learning by doing" modality, with the help when needed of _coaching by the specialist teacher_ for the concrete implementation of the theme in the context of the project.

Choice of themes you will follow:

During the first days of the semester your first choice will be the project topic on which you will have to work with 5 or 6 teammates all along the academic year. Then on this basis and in the next few days you will have to distribute the optional themes (two optional themes per person) so that each theme is represented at least once in your team. Then the themes for which you can not register will be accessible for you if you want through the team's work, with help of your colleagues and the support of the coach.

Content(s)

Content of each theme:

- Design Of Experiments

DOE is a method which allows us to structure a test campaign in order to guarantee the exploitation of the results.

In design, we can thus test new technical solutions, new materials, etc. This method makes it possible to structure both physical and digital tests.

The objectives of this part are:- To know the steps of the method for complete and fractional design of experiments

- To know how to choose the type of plan

- To carry out the process by properly laying the foundations of the study (in particular the identification of the factors potentially influencing the behavior of the system).

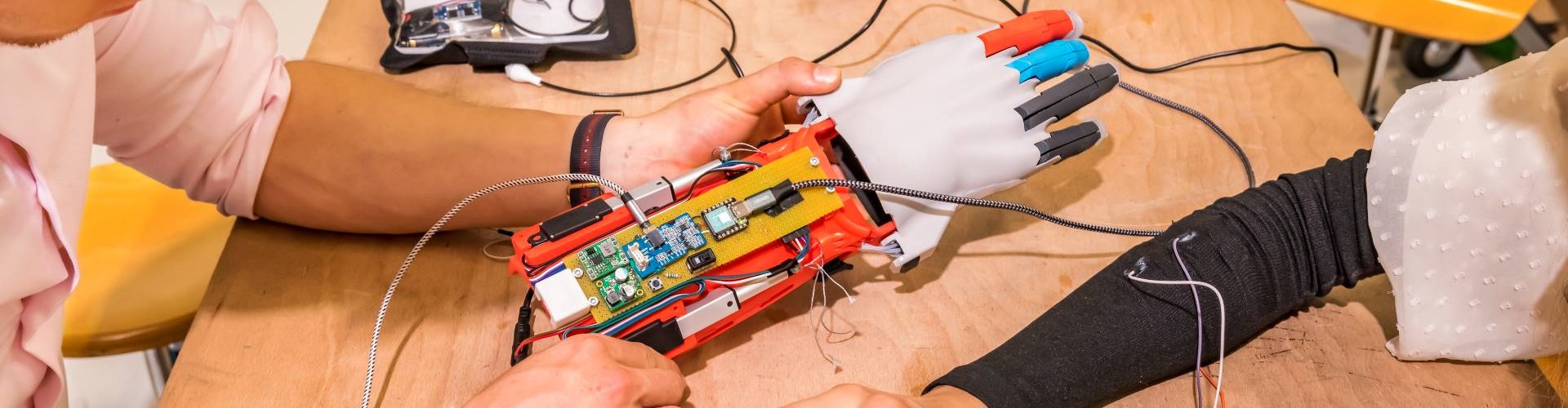

- Prototyping Techniques :

Students will discover the main fabrication techniques available in the workshop, their capabilities, their limits, related machines and software tools. They will learn how to select the most relevant technology to make a part, depending on the shapes, size, constraints, mechanical loads, etc. Learning by practice and case study is the main approach in this theme.

- DFA/DFM

Product design process is built around product specifications. Nevertheless, this not enough to get a product that fits all needs in terms of performance, manufacturing time and cost, as other constraints have to be involved so that the product is easy to produce, with the best quality and cost efficiency. In the lectures about "DFx" (Design for x) machining constraints will be studied through DFM (Design for Manufacturing) and assembly constraints through DFA (Design for Assembly). The aim of these methods is to minimize fabrication and assembly costs by modifying the design taking account of these aspects. EN efficient design can answer the specifications while manufacturing process is also optimized.

- Innovation

TRIZ is a problem solving method which goal is to workaround well known creativity fixation effects. The lecture will go through method principles to setup of some specific tools for problem modeling and problem solving. A few examples will illustrate the concepts and training sessions will allow students to experiment some tools.

- System Engineering, Safety Assessment.

- CM : Model-Based Safety Assessment

- Introduction to Model-Based Systems Engineering (MBSE) and Safety Assessment (MBSA)

- Articulation of MBSE and MBSA

- Model-Based Failure Analysis : design FMECA, Functional (top-down)and Hardware (bottom-up) approaches

- Model-based Reliability Analysis: Fault Tree and Reliability Block Diagram

- Introduction to Model-Based Systems Engineering (MBSE) and Safety Assessment (MBSA)

- TD1 : Tutorial on Model-Based Systems Engineering: from stakeholders needs to systems logical architecture

- TD2 : Tutorial on Model-Based Safety Analysis: from safety requirements to reliability quantification

- CM : Model-Based Safety Assessment

- Project Management

- First module: 3h00 (Start October)

- Project management Introduction

- “Traditional” project management

- “Agile” project management

- Second module: 1h30 (Start October)

- Over view of Project deliverables

- Project deliverables for OPEN:

- Project deliverables for SELECT:

- Third module: 1h30 (January)

- Introduction

- Project deliverables for DO:

- Project deliverables for VERIF/VALID (Verification/Validation):

- First module: 3h00 (Start October)

Written exam. Each student has to answer questions related to the two mandatory themes and the two other themes he has been registered to.

The course exists in the following branches:

- Curriculum - Master 1 GI SIE program - Semester 7

Course ID : WGUS7302

Course language(s):

You can find this course among all other courses.