Number of hours

- Lectures 24.0

- Projects -

- Tutorials 24.0

- Internship -

- Laboratory works -

- Written tests -

ECTS

ECTS 6.0

Goal(s)

The transition from the design phase to the mass production phase requires the consideration of various constraints: technical, organisational, economic and human. In this complex process, the industrialisation engineer plays a key role. The engineer must:

• Take into account the complete 'product life cycle' so as to understand the context and issues.

• Specify and implement optimised production technologies and adapted industrial tools.

• Specify the human resources needed and suggest appropriate organisations, whilst taking into account the changing context.

• Be the interface facilitating dialogue and the exchange of information between the design office, the production service and the purchasing unit.

This course aims at providing the necessary skills for future engineers to set up the different industrialisation phases. It is particularly relevant for future industrial engineers wishing to work with production services as a director and mediator.

Content(s)

Industrialisation and product life cycle (11 hours):

• Study the product life cycle

• Identification of input data for industrialisation: volumes, seasonality of volumes, delivery times, market prices etc...

• Technological environment

• Profitability analysis of a new product

• Industrialisation in the development cycle of a new product

• Industrial methods applied to a product already in production

Industrialisation of components and sub-assemblies (9 hours):

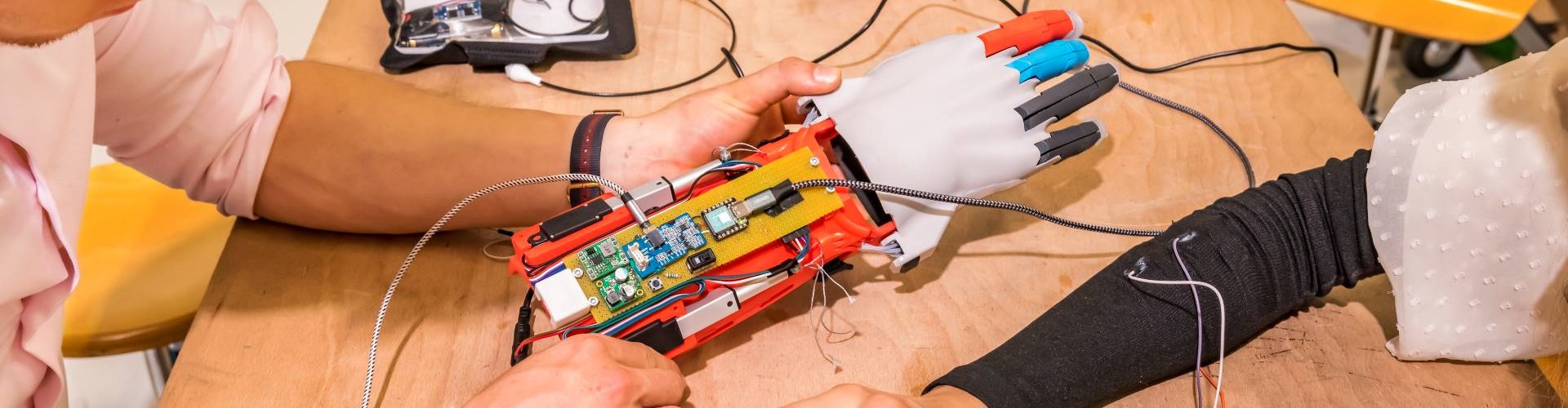

• Component processing: EDM, laser technic, sintering, high speed tooling, tooling design, high speed machining.

• Assembling processes: bolting, gluing, brazing, clipping, welding, moulding, assembly jigs

Illustration through professional presentations (9 h)

• Specific methods for semi-conductors (Teledyne and ST Micro)

. Methods for startups (Start and Fab)

. Industrial strategy (Schneider Electric)

Industrialisation project study case (18 hours):

Small groups of 6 to 8 students will choose one of 4 study cases proposed by industrial companies

Industrialisation project preparation:

• Planning the industrialisation project (key steps)

• Define the organisation and the appropriate resources (resource plan, skills plan, location, transition management, change management...)

• Investment analysis, profitability analysis

• Choice of methods and technologies (make or buy, outsourcing, supplier selection)

First session:

E1 = Final exam assesment (QCM)

E2 = Presentation of Industrialization Technology assesment

E3 = Study case assesment

To validate the course, it is requested to validate the basic skills (20 questions of QCM exam are identified - Mark of 10/20 requested on these specific questions)

Second session: written exam

Session 1:

N = (E1 + 0.25 E2 + 0.75 E3)/2

La validation de l'UE en session demande préalablement d'avoir validé avec 10/20 le socle des connaissances identifiées dans l'examen QCM.

Session 2: examen écrit, 1h

The course exists in the following branches:

- Curriculum - Engineer IPID apprentice program - Semester 9

- Curriculum - Engineer student Master PD - Semester 9

- Curriculum - Engineer student Master SCM - Semester 9

- Curriculum - Master 2 GI GID major GOD - Semester 9

- Curriculum - Master 2 GI SIE program major SPD - Semester 9

- Curriculum - Master 2 GI GID major DPD - Semester 9

- Curriculum - Master 2 GI SIE program major SOM - Semester 9

Course ID : 5GUC1104

Course language(s):

You can find this course among all other courses.

- James M. Morgan, Jeffrey K. Liker, The Toyota Product Development System, Productivity Press, 2006

- Reinersten, D.G., The principles of Product Development Flow, Second Generation Lean Product Development, 2009: Celeritas Publishing

- Tim Brown, Change by design. How design thinking transforms organizations and inspires innovation. 2009: Harper business.

- Yvan Valsecchi, Cours complet de marketing, 2ème édition, Edition Las Cresentinas, 2011

- Robert G Cooper (1990). Stage-Gate Systems: A New Tool for Managing New Products, Business Horizon, May-June 1990.

- Ulrich, K. T. and S. D. Eppinger (2004). Product Design and Development. New York, McGraw-Hill/Irwin.

- François Jakobiak, Pratique de la veille Technologique, Les éditions d’organisation, 1992